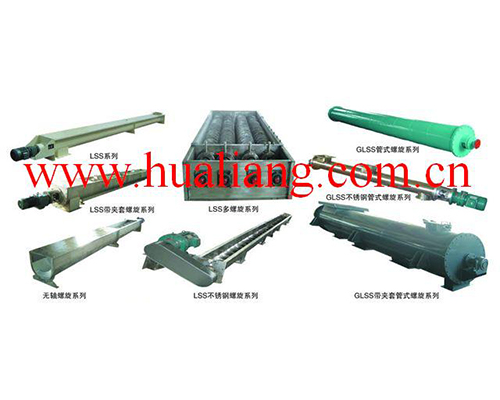

There are many models of screw conveyors, and the functions are quite different. Generally, the following aspects should be considered.

(1) Select the number of display digits and accuracy.

(2) Select the function and measurement range of the screw conveyor.

(3) Select the type of screw conveyor, for example, a popular digital screw conveyor, a multi-function digital screw conveyor, and a dedicated digital screw conveyor. In short, when selecting a digital screw conveyor, it is necessary to start according to the actual work needs, and to ensure that the measurement accuracy and measurement range meet the requirements, as many functions as possible, so that it can be expanded and used in the future. In addition, you should also understand the factors such as the performance of the umbrella and the price/performance ratio.

The shaftless screw conveyor is driven by the motor to drive the cycloidal speed reducer, and is driven by the mechanical seal shaft and the connecting plate on the shaftless spiral body to rotate the screw. When the sludge is discharged to the inlet of the upper portion of the U-shaped groove, That is, the sludge is discharged from the discharge port at the lower part of the U-shaped groove by a screw drive. The sludge in operation is like a non-moving nut, while the shaftless screw is like a rotating bolt. The continuous rotation of the bolt can drive the nut from one end to the other. A horizontally mounted shaftless screw conveyor collects two filter presses and one centrifuge treated sludge simultaneously and transports them to the next process.

Advantages of shaftless screw conveyors in practical applications:

(1) Since the U-shaped groove, the leg, the cover and other components are made of stainless steel, the appearance is beautiful, the structure is compact, and the floor space is small.

(2) The overall structure is relatively simple and there are few parts. The U-shaped groove adopts the segmented flange connection, which is convenient for replacing and repairing the internal bushing. Therefore, the whole machine runs safely and reliably, and the maintenance is convenient. Since the frictionless shaftless spiral body and the U-shaped groove protection bushing material are all high wear-resistant materials, and the spiral rotation speed is low, the wear is small, the service life is long, and the maintenance cost is low.

(3) If the dewatered sludge falls into the feed port, it will not cause scattering and leakage, and will not pollute the environment. In addition, since the upper part of the U-shaped groove is provided with a cover plate, the conveying process is basically closed transportation, so that the indoor odor can be effectively reduced.

(4) During normal operation, maintenance and adjustment are basically unnecessary, which can effectively reduce the labor intensity of operators.