After using the screw conveyor for a period of time, it is necessary to check regularly whether all the bolts are loose. If it is loose, tighten it immediately; check the oil level of the gearbox and the color of the oil. If the oil is insufficient, immediately add oil; check the axial direction of the screw due to fatigue. Stretch, check the amount of wear on the liner, check the electronic control system and safety devices, and so on. If the equipment is found to be abnormally worn, it must be repaired immediately.

The spiral screw conveyor without central axis has its spiral blade always in contact with the surface of the water tank, so the surface of the water tank is covered with a wear pad. If the wear liner is found to be damaged, it should be replaced immediately, as follows.

1. Remove the two tightening caps, the reducer and the bearing seat to connect the flange screws, that is, separate the transmission mechanism.

2. Remove the bearing block and the body connecting screw, and remove the bearing seat, bearing and sealing seat.

3. Take out the spiral.

4. Remove all the platen screws from the bushing and remove the bushing.

5. Replace the new bushing.

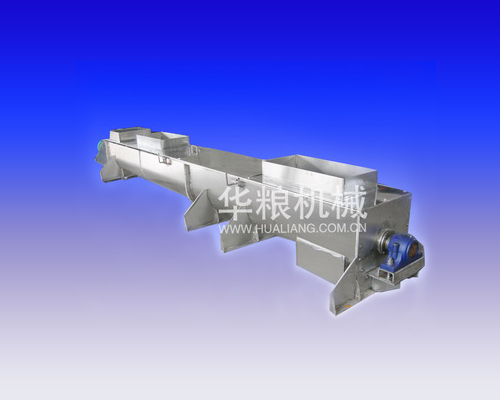

The working principle of the screw conveyor is simple. When it is working, it relies on the driving force of the spiral blade to smoothly transport the product to the designated place. Therefore, the generation of the screw conveyor brings convenience to people's production and life, and it is efficient. The characteristics of energy saving. The screw conveyor products are based on the advanced technology experience of similar foreign products, and continue to innovate and improve on the basis of the original, carefully prepared for you.

The screw conveyor has the advantages of simple structure, low manufacturing cost, strong sealing, safe and convenient operation, and can be loaded and unloaded in multiple places. Widely used in chemical, building materials, metallurgy, food and other departments. The fixed tape conveyor has a simple structure and low cost; the parts have strong versatility and convenient maintenance; and the conveying capacity can meet the usual conditions, thus becoming a mass conveyor. A single or multiple units or a conveyor system that is horizontal or inclined with other conveying equipment as needed.