A pipe branch is arranged on both sides of the active box (slave box) of the pipe chain conveyor, and the branch pipe is connected with the active box (driven box), and the 8-tooth sprocket is installed in the active box (driven box), and the input is The tube is connected by a flange. The two ends of the conveying pipe are respectively connected with the branch pipes arranged on both sides of the active box (the driven box), and the conveying chain is connected to the driving sprocket through the feeding pipe and the inner hole of the branch pipe. The shape of the cross section of the feed pipe is circular. The conveyor chain includes horizontal links and vertical links each having an anchor chain shape, and a disk is fixedly mounted on the vertical links, and the disk is circular. The conveyor has a simple and reasonable structure and can be used in narrow and irregular spaces, and is widely used in material transportation. Depending on the requirements of the user's on-site space, the chain conveyor can be used separately for horizontal, inclined or vertical lifting, and can be used for conveying applications with multiple feed ports or multiple discharge ports. In the bend of the pipe, a reversing sprocket can also be provided for chain reversal.

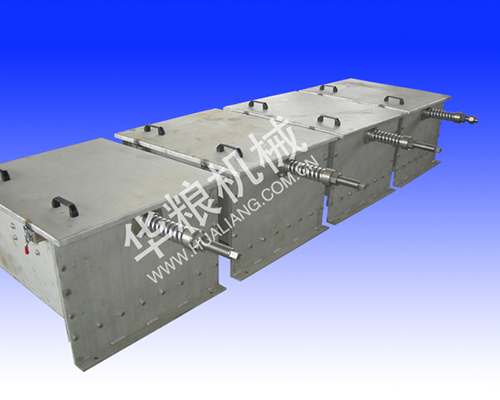

Stainless steel pipe chain conveyor tail advantage:

1. The pipe chain conveyor is simple and compact in structure, and can be arranged horizontally, vertically, curved or three-dimensionally.

2, according to the user's site use, you can multi-feed, multi-port discharge, to achieve a casing chain, multi-point feeding, multi-point discharge.

3. The conveying material is always in a sealed state from the inlet to the outlet flange, and no dust can be leaked into the environment during transportation.

4, the outlet does not need to set up a dust collector, simple exhaust can meet the requirements of modern enterprises for environmental protection.

5. It can be filled with nitrogen gas during transportation to meet the transportation requirements of flammable and explosive powder and granule materials.