The pipe chain conveyor is based on the gravity of the material and the friction generated by the wall of the tank, so that the material can only move forward along the bottom of the conveyor under the push of the blade. Then we should be reasonable when we install the chain conveyor. Let's take a look at the introduction of screw conveyor manufacturers.

The pipe chain conveyor can be mounted on a steel frame on the ground or on the ground, suspended on a wall or roof, installed in a workshop, or installed in a transport corridor or trench. There should be enough space around the conveyor for easy access.

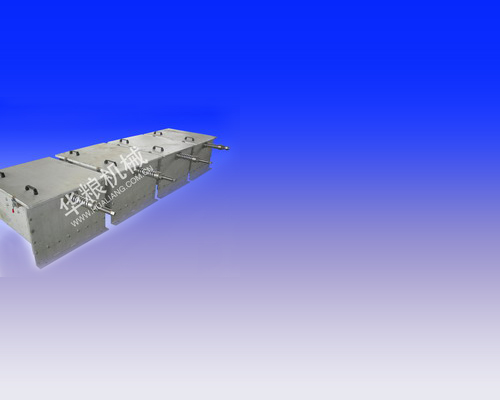

Pipe chain conveyor installation requirements:

The foundation of the pipe chain conveyor should be watered 20 days before the official installation of the screw machine, so that the pipe chain conveyor does not sink or deform after installation, ensuring sufficient stability when the pipe chain conveyor is running.

Assembly housing requirements:

(1) The misalignment of the inner surface of the adjacent casing at the joint should not exceed 3 mm, and the joint of the casing should be tight.

(2) The horizontal level should not exceed 2/1000.

(3) The gap between the inner wall of the casing and the spiral should be equal, and the tolerance of the bottom of the tolerance of ±2 is ±5.

The joints of the pipe chain conveyor must be tightened after all adjustments are made. The low speed shaft of the drive unit and the front shaft of the chain conveyor should be on the same axis.