The scraper conveyor is allowed to bend in both the horizontal and vertical directions (this is designed to accommodate the working and roadway transportation, not to mean that the body is arbitrarily up and down and horizontally curved), but the allowable bending is also certain The limit.

If the scraper conveyor turns "sharp", the bending angle of the chute joint will be too large, causing the chute joint to be overstressed and damaged. After the chute connector is damaged and lost, the chute joint loses control. When there is a gap between the chute joints during bending, the coal powder leaks into the bottom tank, which will increase the running resistance or cause a blockage accident. If the conveyor is not laid flat, the joint wear of the scraper and the chute is intensified at the joint of the chute, increasing the running resistance and shortening the service life, and at the same time causing the shearer to cut the bottom surface of the working surface to make it uneven.

Scraper conveyors must maintain the most critical routine maintenance work:

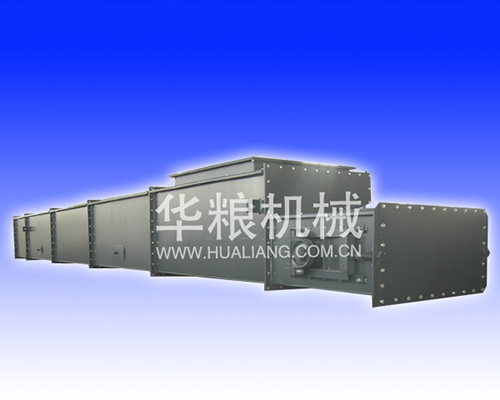

The scraper conveyor is mainly composed of a scraper chain, an electric motor, a transmission device and a trough. According to the arrangement of the trough, the scraper conveyor is divided into two types: side by side and overlap type; according to the number and arrangement of the traction chain, it is divided into three types: medium single chain, medium double chain and double double chain. The strength of the double-stranded chain is large, but the force is uneven. The medium single chain adopts a large model chain with high strength and no uneven force, but it will lead to an increase in the size of the drive sprocket.

The working principle of the scraper conveyor is to use the open chute as a bearing for coal, vermiculite or material, and fix the scraper on the chain (constituting the scraper chain) as a traction member. When the head drive is activated, the sprocket on the driven head shaft rotates, causing the scraper chain to circulate and move the animal material along the chute until the machine head is unloaded. The scraper chain bypasses the sprocket for the infinite closed cycle operation to complete the material transport. Scratches or grooves in the "polyethylene" squeegee may indicate other problems. Regularly check the tightness of all bolted joints and tighten them if they are loose. Regularly remove debris such as hemp rope from the scraper conveyor to avoid overloading the motor after winding the chain and damaging the motor and reducer. Check if the chain pin is broken or loose, replace or repair it in time; check the scraper for damage or wear. If there is a curved deformation or missing blade, replace it or repair it in time. Always check and adjust the tension of the drive belt or chain. Check the chain, rollers and sprocket for excessive wear. Regularly lubricate bearings, gears and reducers in strict accordance with the manufacturer's product specifications. Check all safety devices regularly to make sure they work reliably. For scraper conveyors, maintaining proper chain tension is one of the most critical routine maintenance tasks.