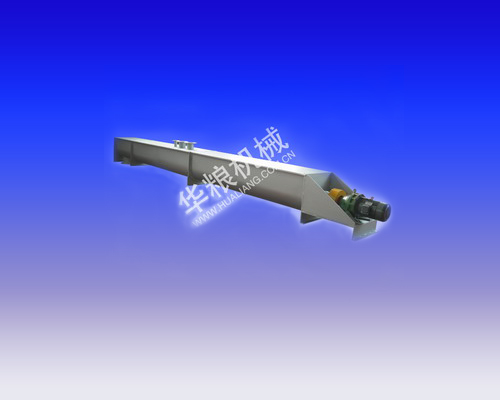

The screw conveyor is a kind of equipment that can continuously convey materials. It has strong conveying capacity, long conveying distance, quick and easy, and strong practicability. Received the love of the majority of users, but the screw conveyor is not suitable for any material conveyor, how to choose the right screw conveyor is a problem that must be considered before purchasing the screw conveyor.

1. The screw conveyor can transport all kinds of powdery and granular materials. The process layout is usually horizontal or inclined less than 20. form.

2. It is not suitable for conveying bulk materials with large temperature, easy to agglomerate and high enthalpy.

3. The design of the screw conveyor should indicate the temperature of the material and the ambient temperature used.

During the use of the screw conveyor, it is necessary to pay attention to the daily maintenance and maintenance, so that it will cooperate with the sand dryer to a large extent to ensure the production volume and efficiency, and also prolong the service life of the equipment.

(1) Lubricate the transmission parts such as bearings, gears and chains at regular intervals.

(2) After the box feeder is deactivated, the spiral blade wear condition should be checked, and the welding should be repaired when the wear is serious.

(3) The conveying amount should not be overloaded, otherwise the material will not be discharged, causing the screw shaft to bend and the box to rise.

(4) When the medium of conveyance is high, it should be noted whether the expansion and contraction of the box is free and there is no jam, if it is solved.