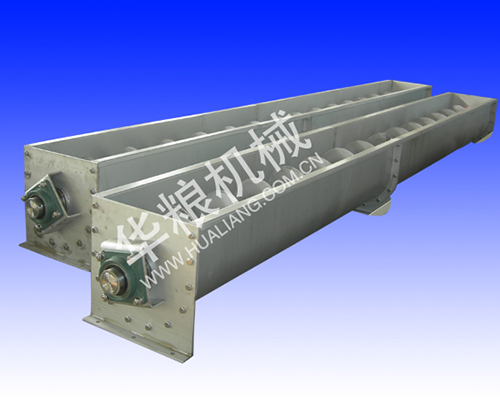

The screw feeder consisting of a specially designed conveying screw seal in the tubular tank enables the material to be output from the silo at a predetermined speed, and the amount of material output is independent of the height of the material. The rotary impeller feeder uses a cylindrical rotating impeller with a specific volume to discharge material at a fast speed. The amount of feed is determined by the rotational speed. It can be driven synchronously with a screw conveyor or separately with a fixed speed or variable speed transmission. Standard discharge is one of the widely used discharge arrangements. The standard discharge port is used to restrain the discharge of the material and directly feed the material to subsequent equipment or storage devices. The terminal discharge is a standard discharge port. However, the discharge port is located at the end of the screw conveyor slot, and the end flange is integrally connected with the end of the slot body.

First, multi-point loading:

It is often required to arrange a conveyor with multiple feeds that is manually adjusted. When only one inlet is required at any given time, the gate or switchgear shall be restricted from overloading the conveyor at the opening. When more than one inlet is required, carefully adjust the flow rate at each inlet so that the total does not exceed the design capacity of the conveyor. The total material flow is controlled when multiple inlets need to be fully opened while feeding to the conveyor.

Second, the unloading discharge port: the material directly falls through an opening at the bottom of the spiral groove. It is generally used for the discharge of the middle of the device, at which point it is not necessary to stop unloading until there is no material drop. For example, for unloading from a magazine.

Third, open bottom discharge: used to discharge materials and fabrics into the hopper, silo or material storage stack. The material is unloaded at any desired length opening at the bottom of the spiral groove of the conveyor. The materials are piled up to form a natural material pile, and the materials that continue from the back are sent to the undischarged place through the pile.

4. Discharge of the end of the spiral trough body: the material is directly discharged through the opening of the end of the spiral conveyor tank. The spiral is supported by a partial end plate and the bearing is mounted on the end flange. This type of unloading method cannot be used when the conveyor fill factor exceeds 0.45.

V. End opening and unloading: The conveyor tail section screw is supported by standard suspension bearings. This type of unloading arrangement can freely discharge materials to the silo or storage pile and similar places.