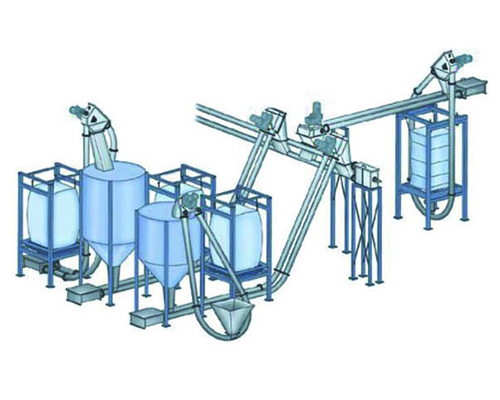

Wire rope chain conveyor

The wire rope chain conveyor is a continuous conveying device with three-dimensional function. It is in the groove of the closed smooth tubular section, and the material and the blade become a continuous by the thrust of the moving blade. The whole is delivered. Because the conveying process is completely closed, it avoids the spillage of material dust, and is widely used in industries such as grain and oil, feed, food, plastics, chemicals, medicine, etc. It is a new type of environmentally friendly conveying equipment.

The pipe chain conveyor is a continuous conveying device for conveying bulk materials such as powder, small particles and small blocks. In the closed pipe, the splicing piece is used as the transmission member to carry the animal material along the pipe. When transported horizontally, the material particles are subjected to the thrust of the chain in the direction of motion. When the internal friction between the layers is greater than the external friction between the material and the pipe wall, the material moves forward with the chain to form a stable flow; when vertically conveyed, the material particles in the pipe are pushed upward by the chain because the lower part The feeding material prevents the upper material from sliding down, and the lateral side pressure is generated, so the internal friction of the material is enhanced. When the internal friction between the materials is greater than the friction between the material and the inner wall of the tube and the weight of the material, the material is transported upward with the chain. A continuous stream is formed.

Advantages of the pipe chain conveyor system:

(1) The structure is compact, the occupied space is small, and the conveying direction can be changed in three dimensions.

(2) It is not necessary to install a dust collector at the exit, and it can be filled with gas when conveying materials.

(3) The material is smoothly conveyed along the pipe, the material is less damaged, and the slow curve conveys so that few material particles generate debris.

(4) Low energy consumption - the most economical operation cost, the whole system has only one motor to drive.

(5) No system blockage - suitable for conveying a variety of materials.