The humidifiers produced by the dust humidification mixers are widely used for the transportation of powdery materials in dry metallurgy, chemical, power plants, boilers and other industries. Specifications are available in SJ series and DSZ series.

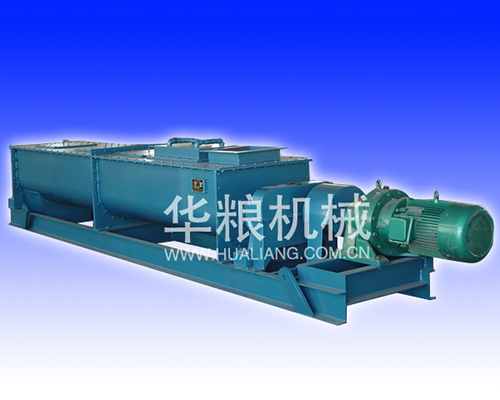

SJ type double-shaft dust humidification mixer is a high-efficiency equipment for spraying and mixing powder materials. It is mainly used in the dust collector of thermal power plants, and can also be used in chemical, metallurgy, mining, building materials and other industries. Appropriate humidity requirements have been achieved by controlling the amount of water added. The two sets of spiral blades are used for agitation, which has the characteristics of high stirring efficiency, small floor space, high wear-resistant special Taiwan gold spiral blade and long service life. The twin-shaft mixer is driven by a cycloidal pinwheel reducer, which has stable rotation and low noise. The twin-shaft mixer feeds from the top, bottom discharge, and structural structure. The seal between the joint surfaces is tight and the operation is stable. The two-axis mixer is equipped with a humidifying water spray system to ensure uniform water spray and adjust the water supply to meet the needs.

Dust humidifiers are used in metallurgy, mining, building materials, chemical, power plants, boilers and other industries to humidify dust and powder materials and transport them to the next process to effectively prevent dust and powdery materials from flying during loading and unloading. A must-have device to avoid environmental pollution.

working principle

The dust collected by the dust collector is passed into the hopper of the DSZ series humidifying mixer through the unloading ash discharge valve. 2. The dust is sent to the spiral conveying blade in the machine body by the rotating impeller. After being screwed into the main cylinder of humidification and stirring, under the uniform mixing of the spiral body, the water spray is evenly injected into the material, and under the action of uniform stirring, the dust is humidified, and the dust after humidification is under the action of multi-column spiral linear thrust. The dust conveying device is discharged from the discharge port and discharged from the outside of the machine. When the spiral body is operated at a constant speed, the vibrating device intermittently operates to oscillate the peripheral wall of the mixing cylinder, and the viscous powder after the humidification is separated from the metal cylinder wall, and is completely sent to the discharge port for discharge.

The machine consists of main body, electric control cabinet, main drive, upper unloader, screw feeder, multi-column linear agitator, vibrator, and multi-tube sprinkler. The whole body is fixed on the base made of channel steel welding. The main body of the conveying mixture is supported by four sets of elastic elements, and is softly sealed and connected with the frame transmission device. The vibration motor is mounted on the top fixing seat of the main cylinder, and the main cylinder body is oscillated synchronously by the vibration device. The main unit deceleration device adopts belt slowing and medium reduction transmission mechanism to completely eliminate the boring and blocking phenomenon, reduce the shutdown cleaning time and improve work efficiency.

Dust humidification mixer Our company's humidifier is widely used in the transportation of powder materials in metallurgy, chemical, power plants, boilers and other industries. Specifications are available in SJ series and DSZ series.

SJ type double-shaft dust humidification mixer is a high-efficiency equipment for spraying and mixing powder materials. It is mainly used in the dust collector of thermal power plants, and can also be used in chemical, metallurgy, mining, building materials and other industries. Appropriate humidity requirements have been achieved by controlling the amount of water added. The two sets of spiral blades are used for agitation, which has the characteristics of high stirring efficiency, small floor space, high wear-resistant special Taiwan gold spiral blade and long service life. The twin-shaft mixer is driven by a cycloidal pinwheel reducer, which has stable rotation and low noise. The twin-shaft mixer feeds from the top, bottom discharge, and structural structure. The seal between the joint surfaces is tight and the operation is stable. The two-axis mixer is equipped with a humidifying water spray system to ensure uniform water spray and adjust the water supply to meet the needs.