Select screw conveyor

(1) Scope and characteristics

(1) Screw conveyor is a kind of conveying equipment widely used in chemical, building materials, grain and other departments. It is mainly used to transport powdery, granular and small pieces of material. It is not suitable for conveying materials that are prone to deterioration, viscous and agglomerated.

(2) The ambient temperature used by the screw conveyor is -20~50°C; the inclination of the conveyor is β≤20°; the conveying length is generally less than 40m and cannot exceed 70m.

(3) Compared with other conveying equipment, the spiral conveying structure is simple, the cross-sectional size is small, the sealing performance is good, the multi-point loading and unloading in the middle, the operation is convenient, and the manufacturing cost is low. Its shortcomings are more serious wear and tear, less conveying capacity, higher power consumption, and easy material damage during transportation.

(2) Classification and structural characteristics

(1) There are three types of spiral blades for screw conveyors: solid spiral surface type, spiral surface type and blade spiral surface type. The solid helix is called the s method, and the spiral pitch GX is 0.8 times the diameter of the blade. The LS screw conveyor is suitable for conveying powdered and granular materials. The belt helicoid, also known as the D method, has the same helical pitch as the diameter of the spiral blade and is suitable for conveying powder and small pieces of material. The blade type spiral surface is used less and is mainly used to convey materials having high viscosity and compressibility. During the transport process, the mixing and mixing processes are completed simultaneously, with a helical pitch of about 1.2 times the diameter of the helical blade.

(2) The spiral blade of the screw conveyor has two directions of left-handed and right-handed.

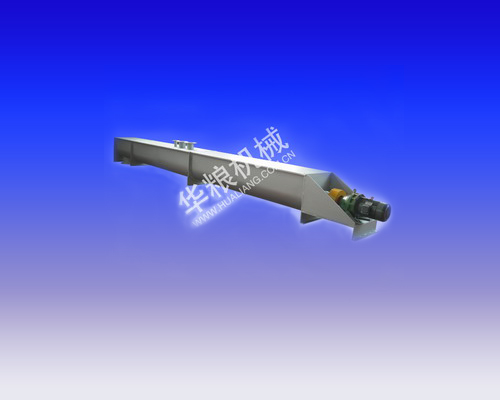

(3) The types of screw conveyors are horizontal fixed screw conveyors and vertical screw conveyors. Horizontal fixed screw conveyors are one of the more common types. Vertical screw conveyors are used to lift materials at short distances. The conveying height is generally not more than 8 meters. Spiral blades are of the solid surface type. It has a horizontal screw feed to ensure the necessary feed pressure.

(4) LS, GX type screw conveyor material outlet end, should be set 1 / 2 ~ 1 reverse spiral to prevent powder clogging.

(5) The screw conveyor consists of three parts: the main body of the screw machine, the inlet and outlet, and the drive unit.

The main body of the screw machine is composed of a head bearing, a tail bearing, a suspension bearing, a screw, a casing, a cover plate and a base. The drive unit consists of a motor, a reducer, a coupling and a base.