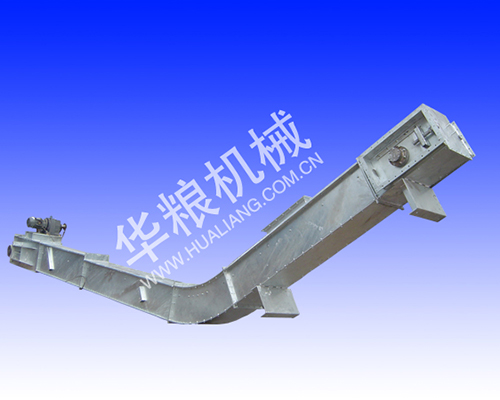

Scraper conveyor retraction sequence

Scraper and scraper chain → scraper conveyor tail and its transmission cooling water pipe and cable → scraper conveyor head and its transmission → head bending transition groove → middle slot and cable trough.

Disassembly, loading and bundling

1. When removing the scraper conveyor, first stop the power lock, then open the chain on the scraper at the transition slot of the machine head, lock the motor of the head to send power to the tail motor, and turn the motor at the tail to turn all the scrapes. The plate chain is spit out and manually pulled to the side of the coal wall to be transported out of the machine lane.

2. After the tail of the scraper conveyor is removed, it is disassembled by the wind lane winch to the lifting device, and the transmission part is removed and loaded separately. The specific method of loading the car is to use two inverted chains to respectively hang the two parts of the parts to lift a certain height, then push the flatbed into the equipment and load the vehicle. When binding, each vehicle is bundled with no less than 6 places, and each place is not less than 6 shares 8# The lead wire is tightly bundled, that is, the 8# lead wire is first bundled and fixed at four corners, and then two Φ 18.5 mm wire rope rope buckles are used to cross-bundle diagonally with the flower bar screws.

3. The tail transition slot and its adjacent two central slots are all transported to the wind lane for loading.

4. After the above work is completed, install the turntable and track laying work, and at the same time prepare for the middle slot.

5. When disassembling the middle slot and the cable trough, first remove the two racks on the side of the coal wall, then remove the cable trough. The two chutes are completely disassembled, and the middle connection dumbbell pin is not removable.

6. The central trough and the cable trough are loaded by inclined platform. The main winch is used to pull the flatbed, and the flatbed is reliably connected with the inclined platform. The auxiliary winch pulls the middle frame for loading. It is required to install one piece, and the binding method is the same as above. The bundling must be firm and reliable. After the equipment is bundled, the auxiliary winch hooks can be removed. Each car requires only two chutes and two cable troughs.

7. After the loading is completed, if there is no problem after inspection, remove the connecting pin between the inclined platform and the flat workshop, remove the auxiliary winch wire rope from the track, use the main winch to lift to the turntable, and use the winch to transport to the +1170m yard.

8. After the disassemble of the scraper conveyor head is also loaded by the inclined platform, the loading and bundling method is the same as that of the middle slot.

9. Before the rear conveyor is recycled, when the rear tail beam inserts are all played out, the left and right sides of the rear conveyor will be cleaned first, and the maintenance of the old airside roof of the rear conveyor will be checked to confirm that there is no hidden danger. Check the support of the upper section of the expansion section. When the support is good, pull out the middle pillar, and after the recovery passage is vacated, start recycling. If the roof support is found to be unreliable after extraction, it must be supported by the shed with the same specifications. .

10. During the disassembly and recovery period, the bracket must be properly supplied with liquid. A special person should check the integrity of the bracket. If there is any other situation such as leakage, it must be disposed of immediately to prevent the tail beam from falling.

11. When the rear conveyor is recycled, it can be divided into two sections for recycling (centered on the 60# bracket), that is, the upper section is top-down and the lower section is recycled from bottom to top.

12. When recycling the tail section of the machine, the wind tunnel back column winch can be used to cooperate with the guide pulley for recycling. The guide pulley is fixed on the mast of the 100# frame tail beam by using the new 40T link or wire rope buckle, and the above section of the 60# frame is pulled out from the space of the 100# frame and dragged to the loading place. Loading and transporting away.

13. The tail conveyor and transmission part of the rear conveyor can be pulled by 5 tons of guide chain. After the recovery of the head section of the rear slide machine, after the top bracket is recovered, the JH-14 type back column winch installed in the machine lane is used together with the guide pulley for recovery, and the guide pulley is used with the new 40T link or The wire rope rope support branch is fixed at the appropriate position of the side rail of the 1# transition frame tail beam, and is pulled out and transported in the machine lane. Loading and bundling methods are the same as before.

14. Before recycling, use two masts at the tail beam of the 60# frame or use the 40T chain to tie the road blocker to prevent the equipment from falling down when recycling the 60# above chute, and hang the metal mesh here. The film, the upper and lower sections are separated to prevent the debris from slipping and hurting after the recycling.

15. When pulling the equipment after pulling, no one should work or stay along the wire rope. The personnel must stand between the two brackets to observe the pulling condition of the equipment. If there is any problem, stop the pulling immediately, and continue to proceed after handling.

16. When pulling equipment after pulling, it is strictly forbidden for personnel to enter or work at the tail beam of the bracket. In order to prevent the back slip, the bracket and the rear slip link chain must not be dismantled in advance. It is necessary to disassemble one piece and transport one piece in order, and the dismantling and transporting should be coordinated. Each pull chute must not exceed 2 knots.

17. When the upper and lower sections are recycled at the same time, special personnel must be sent to observe the drawing of the equipment, and must be unified command and on-site supervision by the on-site team and the team.

18. After the recovery of the rear slide equipment, the upper shed beam and the single pillar are recovered, and two “#” shaped rafts are erected with the old sleeper in time to connect the top sill. The inner side of the raft is aligned with the top line of the 100# bracket tail beam, and the outer side raft is aligned with the front end of the 100# bracket base. When recycling the upper sill beam and the single pillar, it should be recycled from the inside to the outside, and the body sill should be laid before the recycling. The principle of “first support and then return” should be strictly implemented. Recycle the pillars after the connection.