The screw conveyor has a specification for the material conveying. What should the screw conveyor pay attention to when conveying some special materials? Screw conveyor is a kind of conveying equipment widely used in minerals, feed, grain and oil, construction industry, especially in edible materials and engineering construction. Therefore, for the choice of equipment, should be considered again and again.

High-quality screw conveyor requirements for conveying materials, powder, granular and small block materials, such as: cement, coal powder, grain, fertilizer, ash, sand, etc., the temperature of the material shall not exceed 200 ° C, the screw machine is not suitable for transport Deteriorating, viscous, agglomerated material. Because these materials adhere to a spiral when transported, and then rotate without moving forward.

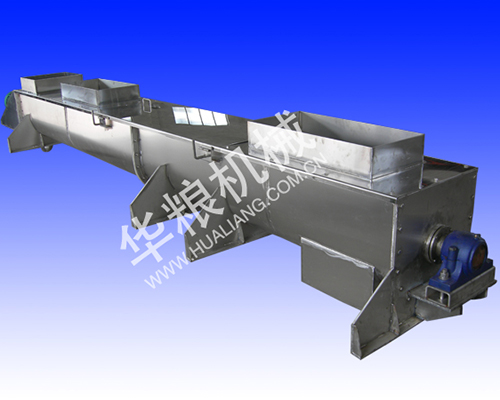

Or the accumulation of material at the sling bearing makes the screw machine not work properly. The working environment of the screw machine should be between -20 °C and 50 °C, allowing a slight tilting, and the large angle of inclination should not exceed 45 °C. The auger conveyor, also known as the 'screw conveyor', is an efficient mining conveyor that has an important position in the field of environmental protection.

Before the screw conveyor is running, first confirm that the screw conveyor equipment, personnel, and articles being transported are in a safe and sound state; secondly, check that each moving part is normal and free of foreign matter, check that all electrical circuits are normal, and that the belt conveyor can be normal. put into service. Finally, check that the difference between the supply voltage and the rated voltage of the device does not exceed ± 5%.

In general, conventional screw conveyors are not suitable for conveying readily, explosive, toxic or corrosive materials. If you need to transport these special materials, please contact Botou Youcheng Machinery Co., Ltd., we will give you advice and use special safety measures for transportation.

According to the requirements of use and the production site, the screw conveyor needs to be arranged reasonably. When it is arranged, it must have a passage and a proper space position for refueling, maintenance and installation. Since the single conveyor speed of the screw conveyor is limited and cannot be bent and conveyed at the same time, several joints are required to be combined into a conveying line.